Thermally modified wood (TMW) is reshaping sustainable construction. Maximo leads this transformation by providing high-performance, chemical-free wood for architects, contractors, and builders. Their responsibly sourced materials offer long-lasting solutions, and this article explores Maximo’s role, diverse products, and efficient distribution strategy for premium thermowood.

How the Thermally Modified Wood Process Works

Thermally modified wood undergoes a specialized heat treatment process that dramatically improves its durability, stability, and resistance to decay. Maximo subjects wood to temperatures ranging from 160°C to 230°C, which alters its structure, reducing its susceptibility to moisture and pests. The key to this process is its eco-friendly nature—no chemicals are used, making it an attractive option for environmentally conscious builders.

Key Benefits of Thermally Modified Wood

- Durability: Greater resistance to decay, insects, and moisture.

- Stability: Reduced warping, swelling, and shrinking. Maximo’s thermally modified wood can retain up to 300% less moisture compared to untreated wood, significantly improving its dimensional stability in various weather conditions.

- Sustainability: Made from sustainably harvested timber, with no chemical treatments required.

- Aesthetics: Thermally modified wood gains a deep, rich color that matures naturally, enhancing its visual appeal.

Thermally modified wood offers several key benefits, including enhanced durability, improved dimensional stability, sustainability through chemical-free processing, and a rich aesthetic appeal that matures naturally over time.

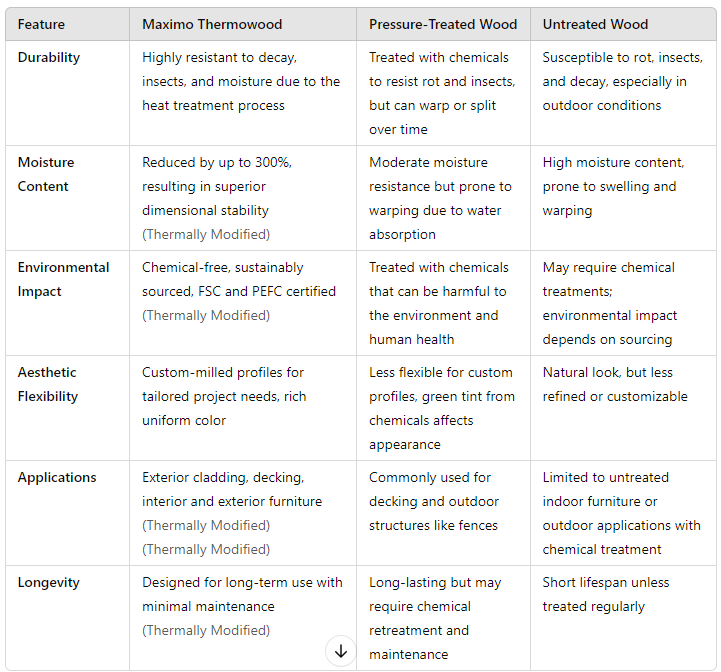

Comparison of Maximo Thermowood, Pressure-Treated Wood, and Untreated Wood

Maximo’s innovative approach to thermally modified wood demonstrates its commitment to balancing sustainability, performance, and aesthetic appeal across a range of premium wood products.

Maximo’s Innovative Approach to Thermally Modified Wood

Maximo stands out in the industry for balancing performance with aesthetic appeal. The company offers several thermowood products, including Scandinavian, Ayous, Ash and Clear Radiata, each known for its unique qualities. Pine, for instance, is lightweight and versatile, perfect for cladding and decking. Ayous, with its premium finish, provides superior resistance to decay, while Ash is valued for its strength and dimensional stability.

Maximo Thermowood: Practical Applications

Maximo’s thermowood excels in a range of applications:

- Exterior Cladding: Ayous and Ash are ideal for cladding due to their moisture resistance and stability.

- Decking: The durability of Scandinavian, Clear Radiata and Ash makes them perfect for outdoor decking, capable of withstanding harsh weather.

- Walls and Ceiling: Scandinavian, Ayous, Ash and Clear Radiata are perfect for interior and exterior walls and ceilings.

These products are often chosen by contractors and builders because they combine beauty and long-lasting performance, minimizing the need for maintenance or frequent replacements.

Maximo provides tailored solutions that meet the needs of both large and small projects with expertise and flexibility.

Maximo’s Client Solutions and Expertise

Maximo’s thermowood is popular among a wide audience:

- Architects and Designers: The wood’s rich aesthetic and environmental benefits appeal to professionals seeking both beauty and performance.

- Contractors and Builders: The wood’s durability, especially in outdoor applications, makes it a go-to for long-term projects.

- DIY Enthusiasts: Homeowners looking for eco-friendly materials appreciate Maximo’s chemical-free products, which offer durability without compromising sustainability.

Maximo’s thermally modified wood serves projects ranging from large commercial constructions to small-scale residential updates, proving its versatility and reliability in various environments.

Maximo’s Custom Milling Capabilities: Tailored Solutions for Large-Scale Projects

Maximo’s custom milling services offer a tailored solution for large-scale projects, allowing architects and builders to achieve precision and flexibility without sacrificing sustainability.

Precision Crafting for Unique Designs

Maximo’s custom milling process allows architects and builders to design with confidence, knowing that their vision will be realized with precision. Whether it’s intricate detailing or unique dimensions, Maximo delivers perfectly milled profiles that meet exact specifications.

Flexibility for Complex Projects

Large-scale projects often demand flexibility in materials and design. Maximo’s ability to accommodate specific project needs—whether for expansive facades or detailed cladding profiles—ensures that the final product is not only functional but visually stunning.

Expertise in Sustainable Milling

Maximo’s milling team combines years of experience with a deep commitment to sustainability. Each custom profile is milled with attention to environmental impact, using only sustainably sourced wood, ensuring that even bespoke designs meet the highest sustainability standards.

Their products are delivered efficiently across North America, ensuring strict quality control from sourcing to final delivery.

Maximo’s Distribution and Supply Chain Strategy

Maximo’s streamlined supply chain ensures the availability of premium wood products in North America.

- By sourcing its wood from sustainably managed forests and performing rigorous quality checks throughout the manufacturing process, Maximo guarantees high-quality materials for every project.

- The company’s well-organized distribution network allows fast delivery across North America, ensuring that builders and contractors receive their materials on time, regardless of project size.

- Maximo ensures that every batch of wood is packed with precision and care, furthering its reputation as a top supplier of thermally modified wood for demanding construction needs.

Driven by a commitment to sustainability, Maximo utilizes innovative techniques and eco-friendly processes to advance the future of construction with durable and recyclable materials.

Leading Innovation in Sustainable Construction

Maximo’s commitment to sustainability is at the core of its operations, as they continue to raise the bar for eco-friendly building materials. By utilizing chemical-free processes and adhering to stringent environmental standards, Maximo offers products that are not only durable but also recyclable and sustainable. This commitment places them at the forefront of the green building movement.

The technical precision with which Maximo manufactures its thermowood ensures that architects, contractors, and builders receive a product that performs exceptionally well under harsh environmental conditions. By offering custom milling options and tailored solutions, Maximo ensures that its products meet the specific needs of each project.

Selecting the Best Thermally Modified Wood for Your Next Build

When it comes to choosing thermally modified wood, durability, moisture resistance, and sustainability are key considerations. Maximo’s thermowood, including Scandinavian, Ayous, Clear Radiata and Ash, offers versatile solutions to meet various project demands.