Thermally modified wood (TMW) has become a popular choice in modern construction due to its remarkable durability, eco-friendly production, and resistance to decay. Builders, architects, and homeowners seeking sustainable materials turn to TMW for its aesthetic appeal and impressive lifespan.

This article explores how long thermally modified wood can last, examining the factors that influence its longevity and best practices for maintenance.

What is Thermally Modified Wood?

Thermally modified wood undergoes a process in which the wood is heated in a low-oxygen environment, typically reaching temperatures between 356°F and 413°F. This high-temperature treatment changes the cellular structure of the wood, reducing its ability to absorb moisture and making it naturally more resilient to decay and insect damage.

Benefits of Thermally Modified Wood

Thermal modification provides several benefits, including:

- Enhanced Durability: The process increases the wood’s natural resilience against decay and insect damage.

- Dimensional Stability: Modified wood has reduced moisture content, making it less likely to warp, shrink, or expand due to temperature and humidity changes.

- Eco-Friendliness: This chemical-free process aligns with sustainable building practices and reduces environmental impact.

Several key factors contribute to the long-term durability and performance of thermally modified wood, making it essential to understand each one for optimal application and maintenance.

Factors Influencing the Lifespan of Thermally Modified Wood

Understanding the longevity of thermally modified wood involves considering the various factors that influence its performance over time. While this treated wood is known for its resilience, aspects like wood species, environmental conditions, and maintenance play significant roles.

Wood Species

Different types of wood respond uniquely to thermal modification. Hardwoods like ash and red oak, for example, are exceptionally durable and can last upwards of 25 years with proper care. Softwoods, such as pine, while also improved by thermal modification, may have a slightly shorter lifespan, making them better suited for lower-traffic or less exposed areas.

Modification Process

The specific temperatures and durations used in thermal modification also impact the wood’s performance and longevity. Higher temperatures increase the wood’s resistance to moisture and decay, though careful balance ensures the wood remains structurally sound. Manufacturers tailor these conditions to each wood species to maximize durability without compromising quality.

Environmental Conditions

Exposure to elements such as sunlight, moisture, and temperature changes affects the longevity of thermally treated wood. While it is designed to withstand these factors, constant exposure to intense UV radiation, for example, can cause surface fading over time, which may require protective measures for exterior applications.

Installation Practices

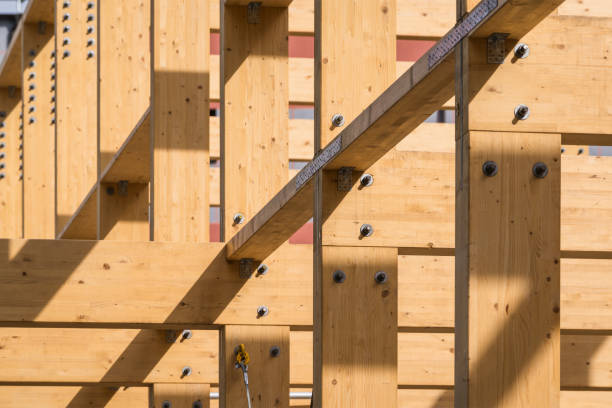

Proper installation is fundamental to extending the life of thermally modified lumber. Ensuring adequate ventilation, especially in decking or siding applications, prevents moisture buildup, which can weaken the wood over time. Using stainless steel fasteners and applying joist tape in decking installations can further protect the wood from potential water damage.

Maintenance

Regular maintenance significantly extends the life of the modified wood. Simple measures, such as cleaning and occasional oiling, keep the wood looking new and help prolong its lifespan. Although this wood requires minimal upkeep compared to untreated alternatives, routine care adds value over the years.

When comparing thermally modified wood with untreated wood, the advantages in longevity and resilience become especially clear.

Thermally Modified Wood vs. Untreated Wood: A Comparative Analysis

Thermally modified wood offers a much longer lifespan than untreated wood due to its natural resistance to decay and pests. While untreated wood may last up to 10-15 years outdoors (depending on the species), thermally treated wood can maintain structural integrity for 25 years or more in similar conditions. For applications such as decking or siding, this extended lifespan makes it a valuable choice, reducing the need for frequent replacements and repairs.

- Resistance to Decay and Insects – The thermal modification process alters the wood’s organic compounds that typically attract insects and promote fungal growth. As a result, thermally treated lumber naturally resists both decay and insect damage, unlike untreated wood, which may require chemical treatments to achieve a similar level of protection.

The versatility of thermally modified wood across various applications highlights its impressive durability and adaptability in different environments.

Applications and Lifespan Expectations for Thermally Modified Wood

Thermally modified wood is suitable for a wide range of uses, with its longevity varying by application and exposure level. Here are a few common applications and what to expect in terms of durability.

Decking

Thermally treated wood’s resilience to moisture and decay makes it ideal for decking, where wood is frequently exposed to the elements. With proper installation and routine maintenance, thermally modified decking can last up to 25 years, even in humid or rainy climates.

Siding and Cladding

For siding and cladding, thermally modified wood provides a long-lasting, aesthetically pleasing solution that performs well across diverse climates. In drier regions, TMW siding may last beyond 30 years, while in more challenging environments, such as coastal or high-humidity areas, a lifespan of 20-25 years is expected.

Natural Aging and Patina Development

Thermally modified wood not only offers durability but also develops a unique, natural beauty as it ages. When exposed to the elements without protective treatments, TMW gradually transforms into a silver-gray patina over time. This aging process is purely aesthetic and does not compromise the wood’s structural integrity, making it an attractive choice for those who appreciate a weathered look in outdoor applications like decking, siding, and cladding.

Outdoor Furniture

Outdoor furniture made from this modified wood is a sustainable choice with excellent durability. Resistant to decay and pests, thermally treated furniture can last over two decades with minimal upkeep, making it a popular option for homeowners and landscape designers alike.

As seen in these applications, regular care practices contribute greatly to maximizing the lifespan of this unique wood product.

Maintenance Tips to Extend the Life of Thermally Modified Wood

Routine maintenance ensures that thermally treated wood remains strong, attractive, and resilient over the years. Here are some recommended practices:

- Regular Cleaning: Periodic cleaning prevents the buildup of dirt and organic materials, which can attract moisture. Simply washing with water and a mild soap can maintain the wood’s natural appearance.

- Protective Treatments: Although thermally modified wood does not require chemical preservatives, applying a protective oil or sealant helps prevent fading and surface wear, especially for outdoor applications. Reapplying these treatments every 1-2 years shields the wood from UV exposure and helps retain its color.

- Routine Inspections: Checking for cracks, loose fasteners, or other wear allows for early repairs, preserving the wood’s structure and extending its life.

Transitioning to sustainability, it’s clear that thermally modified wood’s benefits extend beyond just durability.

Sustainability Benefits of Thermally Modified Wood

Thermally modified wood is recognized for its eco-friendly properties, largely because the modification process requires no chemicals. This chemical-free treatment allows TMW to meet rigorous environmental standards, making it an ideal choice for sustainable building. Additionally, the process often utilizes fast-growing species, reducing reliance on endangered hardwoods and supporting responsible resource management.

Recyclable and Environmentally Friendly

Thermally modified wood stands out not only for its durability during use but also for its eco-friendliness at the end of its life cycle. Unlike chemically treated woods, TMW is fully recyclable, allowing it to be repurposed or disposed of without harmful environmental impact. This sustainability advantage makes TMW an ideal choice for those seeking environmentally conscious materials that maintain their green credentials from installation through to eventual recycling or reuse.

In addition to extending the lifespan of these wood products, using thermally modified wood helps builders and designers create structures that align with environmental goals, conserving resources over the long term.

Investing in Longevity with Thermally Modified Wood

Choosing thermally modified wood offers an opportunity to balance durability, moisture resistance, and environmental sustainability in your project. Different wood species, such as Pine, Ayous, and Ash, each offer unique characteristics to fit a variety of structural and aesthetic needs.

With a lifespan of 20-30 years, this treated wood stands as a sustainable, long-lasting alternative to chemically treated or untreated wood.